Electrical System Commissioning & Start-Up Services

Nearly 70% of early equipment failures can be traced to design, installation or start-up deficiencies. Similarly, newly launched plants experience many unnecessary outages due to improper coordination and calibration of protective devices, wiring errors, design errors, etc.. In other cases, the failures don’t occur until months after the facility has gone into operation and the warranties have expired. Loose connections or insulation damage may not show up until more equipment comes online and electrical loads increase.

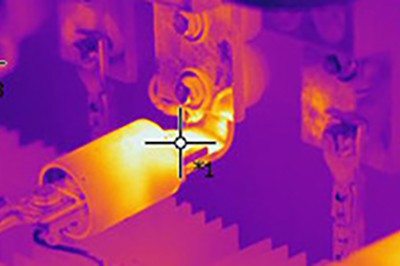

The inspection and testing performed on an electrical power system and its components before initial energization is perhaps the most important preventive maintenance that the system and/or components will receive during their operational life.

When normal start-up testing isn’t performed (usually to save a few dollars), the results can be disastrous. Perfectly good switchgear, transformers or other equipment can be “smoked” due to relatively small installation errors.

Pace Technologies Commissioning & Startup Services for electrical distribution systems can verify that the equipment has been properly installed. We’ll also determine whether any equipment has been damaged during shipment or installation and ensure that your equipment complies with the purchase specifications and design intent.

Using Pace Technologies Commissioning and Startup services will help ensure that your newly installed equipment operates efficiently as an integrated system. Properly done, commissioning projects can pay dividends in the form of decreased rework, fewer change orders, fewer delays, lower operation and maintenance costs, and lower utility bills.

Commissioning and startup testing also provides valuable baseline or benchmark information that can be used to evaluate future maintenance decisions.